Graphite or Copper EDM Electrodes

Taiyou manufacturers all the EDM electrodes needed by our own Sinker EDM manufacturing, also provide contract manufacturing jobs for customers.

Sinker EDM, also been called conventional EDM, plunge EDM and ram EDM, is the method of choice for difficult to machine materials and features that cannot be machined any other way.

Sinker EDM can be applied to hard materials including stainless steel, copper, that would cause difficulties during conventional machining. In addition, sinker EDM is advantageous due to its ability to create complex parts with a high degree of accuracy. Also, the work piece is not deformed because there is no direct contact between the electrode and the material, and likewise the work piece is burr-free after completion and saved from heat damage because very little material-damaging heat is generated during the procedure. Sinker EDM has an advantage over wire EDM as well, because sinker EDM does not cut all the way through the material, thus producing parts that wire EDM cannot.

Advantages and Benefits

- Unique Cavity Shapes

- Sharp Internal Corners

- Small Holes

- Works for any conductive material

- Difficult to machine material

There are 2 types of material which often used for electrodes:

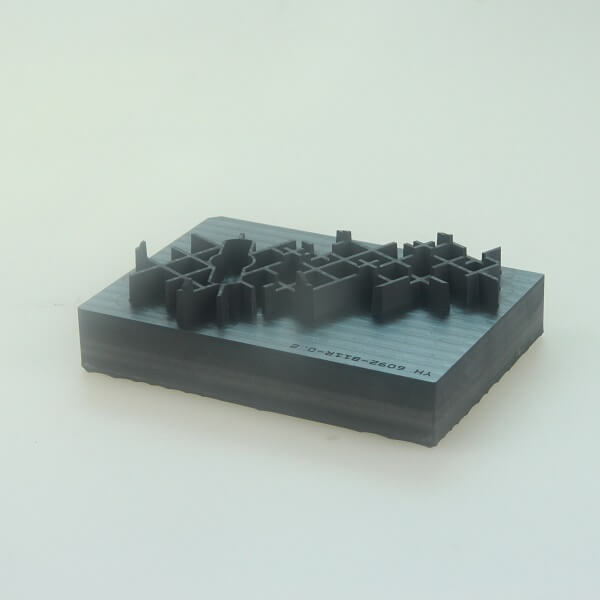

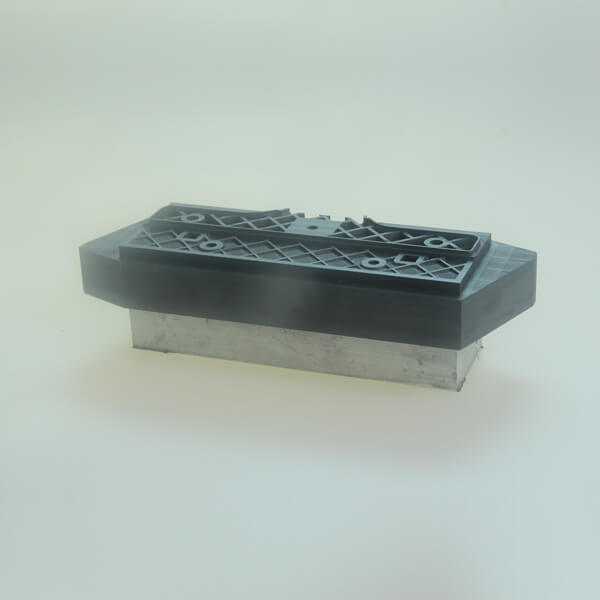

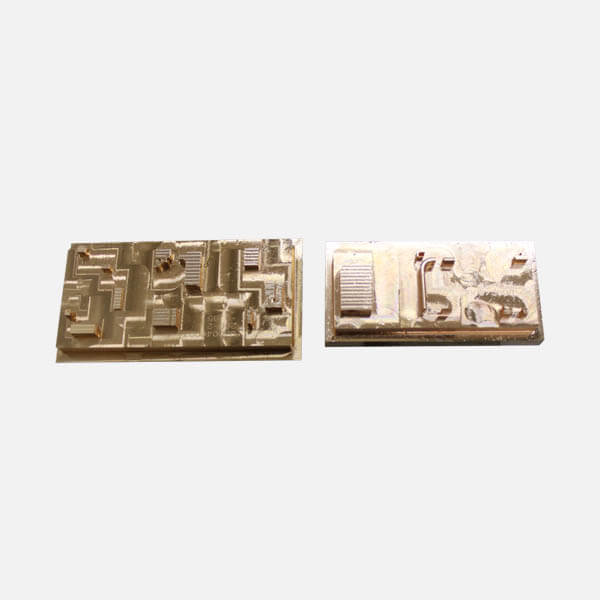

*Graphite electrode

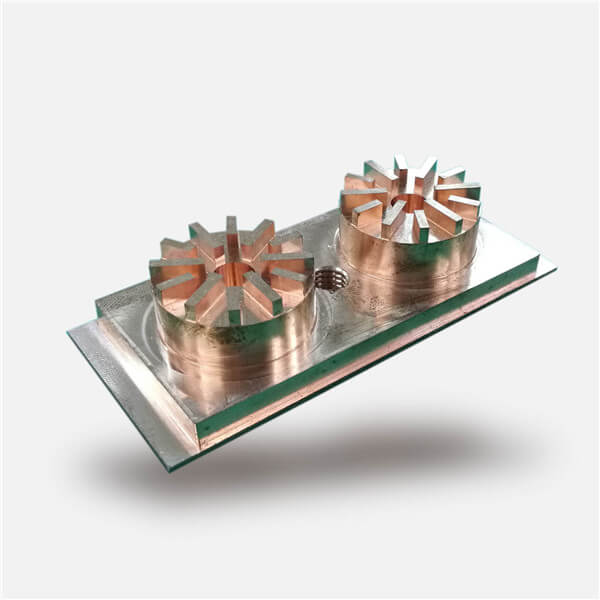

*Copper electrode

Customer can choose material based on their applications.

Ready to find out more?

Drop us a line today for a free quote!