About Us

We believe our customers' needs are the most important. Most of our new business is introduced by old customers for our good reputation.

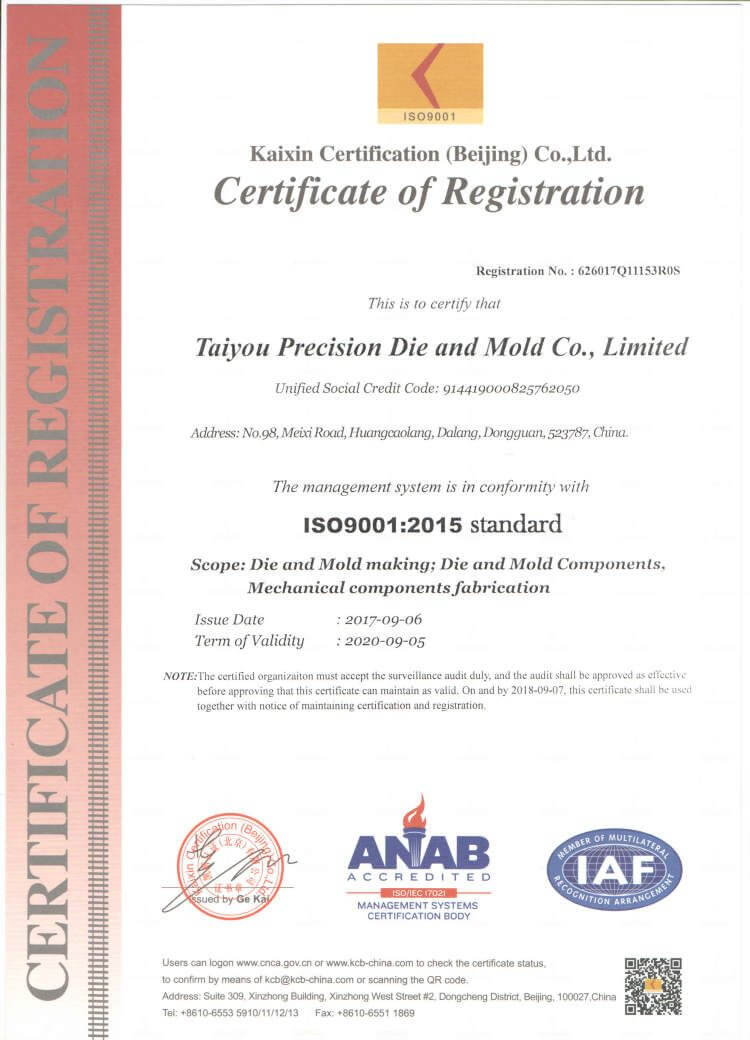

Our services including precision Wire cutting, CNC machining, CNC lathe, grinding of tool steels,stainless steels for plastic molds,stamping tools,casting dies. Unlike other companies that sell everything component-related, we sell only custom components. Taiyou is good at manufacturing of complex and precision custom mold and die components, such as cavities and cores, pins, slides,tool plates, punches and dies, inserts etc, as well as jigs and fixtures.

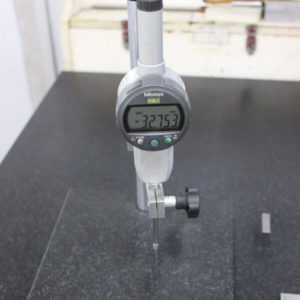

Capabilities include custom parts with diameters ranging from 0.2 to 220 mm, lengths up to 1000mm, with tolerances down to +/-0.001mm, coaxiality 0.003 mm, circularity 0.0015 mm, surface finishes as best as Ra0.025.

Majorly serving the automotive, medical and electronics industries.

We would welcome the opportunity to earn your trust and deliver you the best service in the industry. Once you try us, you will never regret.

Our Manufacturing Equipments

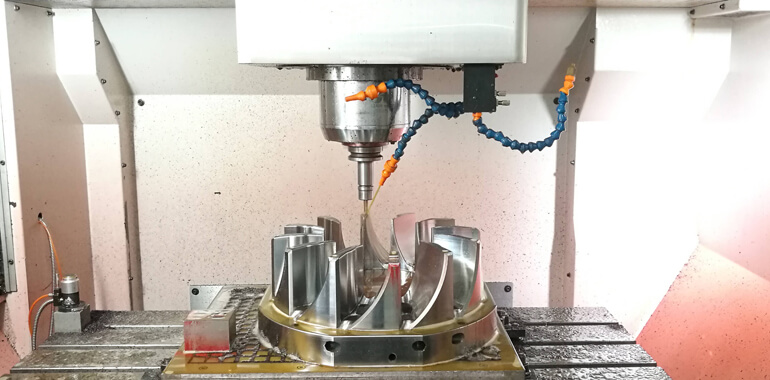

Taiyou is equiped with advanced machinery of all procedures in house, including Wire EDM, Sinker EDM, CNC machining, CNC lathe, Drilling, Grinding, Polishing, offer comprehensive technique, to assure the best quality of component needs, and bring the cost down for customers.

Sodick Wire EDM

Sodick

Range: 350*260*250mm

Precision: 0.002mm

CNC Lathe

LongZe

Range: Dia 1.0-320mm

Precision: 0.005mm

Centerless Grinder, O.D.& I.D. Grinder

Jianhe

Range:Dia 0.35-60m

Precision: 0.001

Makino Sinker EDM

MAKINO Edge 2 and Edge 3

Precision: 0.002mm

CNC engraving machine

Brand: Beijing JD

Precision:0.005mm

For CNC engraving of copper electrodes which will be used on our Sinker EDMs.

CNC machining center

Gentiger

Range:1100*600*500mm

Precision:0.005mm

Surface grinder

FuYu

Range:850*650*200mm

Precision:0.002mm

Ready to find out more?

Drop us a line today for a free quote!